Pyroelectric Energy Sensors (C-Series)

- Energy Ranges Covering 10 µJ to 15 J

- Repetition Rates of Up to 10 kHz

- Wavelength Ranges Covering 185 nm to 25 µm

- BNC to C-Series Adapter included

High Energy Sensors with Ceramic Coating (Shown with Included Isolator, Post Not Included)

ES220C

ES245C

Standard Sensors with Black Coating (Shown with Included Isolator, Post Not Included)

ES312C

Black Coating

ES120C

ES145C

ES408C

Metal Coating

Fast Sensors for High Repetition Rates

(Post Not Included)

Please Wait

| Type | Standard | High Energy | Fast | |

|---|---|---|---|---|

| Item # | ES1xxC | ES2xxC | ES3xxC | ES4xxC |

| Energy Range | 10 µJ - 2 J | 500 µJ - 15 J | 100 µJ - 1 J | 50 µJ - 1 J |

| Wavelength Range | 0.185 - 25 µm | 0.185 - 25 µm | 0.185 - 25 µm | 0.185 - 2.5 µm |

| Max Power Density (Pulse Width) |

8 MW/cm2 (10 ns Pulse) |

65 MW/cm2 (7 ns Pulse) |

8 MW/cm2 (10 ns Pulse) |

5 MW/cm2 (10 ns Pulse) |

| Repetition Rate | 30 Hz - 40 Hz | 30 Hz | 250 Hz - 1 kHz | 2 kHz - 10 kHz |

| Coating | Black | Ceramic | Black | Metal |

| Typical Application | Wavelength-Independent Energy Measurements | High Energy Densities | High Repetition Rates | |

| Power Meter Selection Guide |

|---|

| Sensors |

| Photodiode Power Sensors |

| Thermal Power Sensors |

| Thermal Position & Power Sensors |

| Pyroelectric Energy Sensors |

| Power Meter Consoles and Interfaces |

| Digital Handheld Console |

| Analog Handheld Console |

| Touchscreen Handheld Console |

| Dual-Channel Benchtop Console |

| USB Interfaces with External Readout |

| Complete Power Meters |

| Power Meter Bundles |

| Wireless Power Meters with Sensors |

| Compact USB Power Meters |

| Field Power Meters for Terminated Fibers |

Click to Enlarge

Click to EnlargeThese pyroelectric sensor heads are terminated with a BNC connection. A BNC to C-Series adapter is included for use with C-Series Power Meter Consoles or Interfaces.

Features

- For Pulsed Applications Over a Wide Wavelength and Energy Range

- Individually Calibrated with NIST- and PTB-Traceable Certificate of Calibration

- BNC Connector for Direct Use with Oscilloscopes

- BNC to C-Series Adapter Includes Calibration and Indentification Data

- Compatible with Select C-Series Energy Meter Consoles and Interfaces (See Tables Below for Details)

Thorlabs' Pyroelectric Energy Meter Sensors can be used to detect pulsed sources with energies from 10 µJ to 15 J. All of these sensors provide a flat response over the 185 nm to 25 µm wavelength range except for the ES4xxC sensors, which have a range from 185 nm to 2.5 µm (see the Absorption Graphs tab for details). Note that pyroelectric sensors are not suited for CW measurements, as they convert energy from light pulses into voltage pulses.

The ES1xxC standard sensors can be used for wavelength-independent energy measurements of sources with energies from 10 µJ to 2 J and repetition rates up to 40 Hz. The ES2xxC sensors are designed to handle high power densities up to 65 MW/cm2 (for a 7 ns pulse width). For sources with repetition rates up to 1 kHz, the ES3xxC fast energy sensors can detect sources with energies bewteen 100 µJ to 1 J over a broad wavelength from 185 nm to 25 µm. For higher repetition rates up to 10 kHz, the ES4xxC sensors can detect sources with energies 50 µJ to 1 J at wavelengths up to 2.5 µm.

Compatibility

All of Thorlabs' pyroelectric energy sensors are compatible with the PM5020 benchtop console and PM103x power and energy meter interfaces, and all the sensors except for Item # ES408C are compatible with the PM400 and PM100D power and energy meter consoles and PM100USB interface. Please see the Console Selection tab for a summary of our console and interface options.

Alternatively, the sensors can be connected directly to an oscilloscope with a 1 MΩ input resistance via the BNC connector. For the ES1xxC standard and ES2xxC high-energy sensors, the load resistance can be reduced when connected to an oscilloscope to accommodate higher repetition rates. The ES3xxC and ES4xxC fast energy sensors, which can detectect repetition rates ≥250 Hz, are optimized for use with 1 MΩ loads, and using these sensors with other load resistances may lead to reduced speed.

The bottom of the sensor head has a mounting hole with either 8-32 threads (ES1xxC and ES2xxC sensors) or 8-32 and M4 combi-threads (ES3xxC and ES4xxC sensors). Since the heads of the ES1xxC and ES2xxC sensors are very sensitive to ground loops and electrical noise, we recommend attaching the sensor head to one of the included electrically isolating post adapters; one imperial and one metric adapter are included with each sensor head to provide direct compatibility with imperial or metric Ø1/2" (Ø12.7 mm) Posts. The design of the ES3xxC and ES4xxC sensors means that adapters for electrical isolation are not necessary. The ES120C and the ES220C can also be mounted to our 30 mm Cage System via the four 4-40 threaded holes on the front, although this mounting option does not provide electrical isolation. The ES3xxC and ES4xxC sensors have externally SM1-threaded (1.035"-40) input apertures for use with our SM1-threaded lens tubes.

Calibration

Each sensor head is individually calibrated and is shipped with a NIST- and PTB-Traceable Calibration Certificate. The calibration and identification data is stored in the BNC to C-Series adapter, shown in the image above, and is downloaded automatically when connected to a compatible Thorlabs' console or interface.

Recalibration Services

Thorlabs offers recalibration services for our pyroelectric energy sensors. To ensure accurate measurements, we recommend recalibrating the sensors annually. Pyroelectric energy sensors returned for recalibration or servicing must include the separate BNC to DB9 adapter, which contains the sensor EEPROM. To order this service for your sensor, scroll to the bottom of the page and select Item # CAL-THPY. Recalibration of a single-channel power and/or energy meter console or interface is included with the recalibration of a sensor at no additional cost.

| Item # | ES111C | ES120C | ES145C | ES220C | ES245C |

|---|---|---|---|---|---|

| Technical Specs | |||||

| Detector Type | Standard Pyroelectric Energy Sensor | High-Energy Pyroelectric Energy Sensor | |||

| Wavelength Range | 185 nm - 25 µm | 185 nm - 25 µm | |||

| Optical Energy Range | 10 µJ - 150 mJ | 100 µJ - 500 mJ | 500 µJ - 2 J | 500 µJ - 3 J | 1 mJ - 15 J |

| Max Repetition Rate (@ 1 MΩ Load) |

40 Hz | 30 Hz | 30 Hz | 30 Hz | 30 Hz |

| Max Power Density (Pulse Width) |

8 MW/cm2 (10 ns Pulse) |

65 MW/cm2 (7 ns Pulse @ 355 nm) |

|||

| Max Pulse Energy Density (Pulse Width) |

0.15 J/cm2 (1 µs Pulse) |

0.45 J/cm2 (7 ns Pulse @ 355 nm) |

|||

| Max Average Power | 0.15 W | 0.15 W | 0.5 W | 5 W | 10 W |

| Resolution | 100 nJ | 1 µJ | 1 µJ | 25 µJ | 50 µJ |

| Linearity | ±1% | ±1% | |||

| Measurement Uncertainty | ±5% @ 190 nm - 25 µm | ±5% @ 185 nm - 25 µm | ±5% @ 185 nm - 25 µm | ±5% @ 185 nm - 25 µm | |

| Thermal Time Constant | 20 ms | 20 ms | |||

| Item # | ES308C | ES312C | ES408C | ES412C |

|---|---|---|---|---|

| Technical Specs | ||||

| Detector Type | Fast Pyroelectric Energy Sensor | |||

| Wavelength Range | 185 nm - 25 µm | 185 nm - 2.5 µm | ||

| Optical Energy Range | 500 µJ - 1 J | 100 µJ - 1 J | 100 µJ - 1 J | 50 µJ - 500 mJ |

| Max Repetition Rate (@ 1 MΩ Load) |

1 kHz | 250 Hz | 10 kHz | 2 kHz |

| Max Power Density (Pulse Width) |

8 MW/cm2 (10 ns Pulse) |

5 MW/cm2 (10 ns Pulse) |

||

| Max Pulse Energy Density (Pulse Width) |

80 mJ/cm2 (10 ns Pulse) |

50 mJ/cm2 (10 ns Pulse) |

||

| Max Average Power | 0.5 W | 0.5 W | ||

| Resolution | 5 µJ | 1 µJ | 1 µJ | |

| Linearity | ±1% | ±1% | ||

| Measurement Uncertainty | ±5% @ 185 nm - 25 µm | ±5% @ 185 nm - 2.5 µm | ||

| Thermal Time Constant | 0.6 ms | 2 ms | 0.07 ms | 0.5 ms |

For details on sensor-related terminology, see our list of definitions.

Click to Enlarge

Click Here for Raw Data

Click to Enlarge

Click Here for Raw Data

Click to Enlarge

Click Here for Raw Data

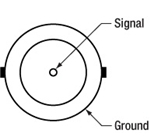

C-Series Connector Adapter

D-Type Male

| Pin | Connection |

|---|---|

| 1 | Not Used |

| 2 | EEPROM Data |

| 3 | Pyroelectric Sensor Ground |

| 4 | Not Used |

| 5 | Pyroelectric Sensor + |

| 6 | EEPROM Ground |

| 7 | Present: Sensor Recognition |

| 8 | Not Used |

| 9 | Not Used |

Sensor Connector

BNC Male

Thorlabs offers a wide selection of power and energy meter consoles and interfaces for operating our power and energy sensors. Key specifications of all of our power meter consoles and interfaces are presented in this tab to help you decide which device is best for your application. We also offer self-contained wireless power meters and compact USB power meters.

When used with our C-series sensors, Thorlabs' power meter consoles and interfaces recognize the type of connected sensor and measure the current or voltage as appropriate. Our C-series sensors have responsivity calibration data stored in their connectors. The console will read out the responsivity value for the user-entered wavelength and calculate a power or energy reading.

- Photodiode sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current. The photodiode's responsivity is wavelength dependent, so the correct wavelength must be entered into the console for an accurate power reading. The console reads out the responsivity for this wavelength from the connected sensor and calculates the optical power from the measured photocurrent.

- Thermal sensors deliver a voltage proportional to the input optical power. Based on the measured sensor output voltage and the sensor's responsivity, the console will calculate the incident optical power.

- Energy sensors are based on the pyroelectric effect. They deliver a voltage peak proportional to the pulse energy. If an energy sensor is recognized, the console will use a peak voltage detector and the pulse energy will be calculated from the sensor's responsivity.

The consoles and interfaces are also capable of providing a readout of the current or voltage delivered by the sensor. Select models also feature an analog output.

Consoles

| Item # | PM100A | PM100D | PM400 | PM5020 |

|---|---|---|---|---|

| (Click Photo to Enlarge) |  |

|

|

|

| Key Features | Analog Power Measurements | Digital Power and Energy Measurements | Digital Power and Energy Measurements, Touchscreen Control | Dual Channel |

| Compatible Sensors | Photodiode and Thermal Power | Photodiode Power, Thermal Power, and Pyroelectric Energya | Photodiode Power, Thermal Power, Thermal Power and Position, and Pyroelectric Energya | Photodiode Power, Thermal Power, Thermal Power and Position, and Pyroelectric Energy |

| Housing Dimensions (H x W x D) |

7.24" x 4.29" x 1.61" (184 mm x 109 mm x 41 mm) |

7.09" x 4.13" x 1.50" (180 mm x 105 mm x 38 mm) |

5.35" x 3.78" x 1.16" (136.0 mm x 96.0 mm x 29.5 mm) |

9.97" x 4.35" x 11.56" (253.2 mm x 110.6 mm x 293.6 mm) |

| Channels | 1 | 2 | ||

| External Temperature Sensor Input (Sensor not Included) | - | - | Readout and Record Temperature Over Time | Readout and Record Temperature Over Time |

| External Humidity Sensor Input (Sensor not Included) | - | - | Readout and Record Humidity Over Time | Readout and Record Humidity Over Time |

| Input/Output Ports | - | 4 GPIO, Programmable | 4 Configurable Digital I/O Channels | |

| Shutter Control | - | - | - | Support for SH05R(/M) or SH1(/M) Optical Shutter with Interlock Input |

| Fan Control | - | - | - | |

| Source Spectral Correction | - | - | ||

| Attenuation Correction | - | - | ||

| External Trigger Input | - | - | - | |

| Display | ||||

| Type | Mechanical Needle and LCD Display with Digital Readout | 320 x 240 Pixel Backlit Graphical LCD Display | Protected Capacitive Touchscreen with Color Display | |

| Dimensions | Digital: 1.9" x 0.5" (48.2 mm x 13.2 mm) Analog: 3.54" x 1.65" (90.0 mm x 42.0 mm) |

3.17" x 2.36" (81.4 mm x 61.0 mm) |

3.7" x 2.1" (95 mm x 54 mm) |

4.32" x 2.43" (109.7 mm x 61.6 mm) |

| Refresh Rate | 20 Hz | 10 Hz (Numerical) 25 Hz (Analog Simulation) |

25 Hz | |

| Measurement Viewsb | ||||

| Numerical | ||||

| Mechanical Analog Needle | - | - | - | |

| Simulated Analog Needle | - | |||

| Bar Graph | - | |||

| Trend Graph | - | |||

| Histogram | - | - | - | |

| Statistics | ||||

| Memory | ||||

| Type | - | SD Card | NAND Flash | SD Card |

| Size | - | 2 GB | 4 GB | 8 GB |

| Power | ||||

| Battery | LiPo 3.7 V 1300 mAh | LiPo 3.7 V 2600 mAh | - | |

| External | 5 VDC via USB or Included AC Adapter | 5 VDC via USB | Line Voltage: 100 - 240 V | |

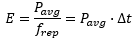

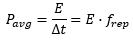

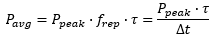

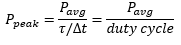

Pulsed Laser Emission: Power and Energy Calculations

Determining whether emission from a pulsed laser is compatible with a device or application can require referencing parameters that are not supplied by the laser's manufacturer. When this is the case, the necessary parameters can typically be calculated from the available information. Calculating peak pulse power, average power, pulse energy, and related parameters can be necessary to achieve desired outcomes including:

- Protecting biological samples from harm.

- Measuring the pulsed laser emission without damaging photodetectors and other sensors.

- Exciting fluorescence and non-linear effects in materials.

Pulsed laser radiation parameters are illustrated in Figure 170A and described in Table 170B. For quick reference, a list of equations is provided below. The document available for download provides this information, as well as an introduction to pulsed laser emission, an overview of relationships among the different parameters, and guidance for applying the calculations.

|

Equations: |

||||

|

and |  |

||

|

||||

|

||||

|

||||

Peak power and average power calculated from each other: |

||||

|

and |  |

||

| Peak power calculated from average power and duty cycle*: | ||||

|

*Duty cycle ( ) is the fraction of time during which there is laser pulse emission. ) is the fraction of time during which there is laser pulse emission. |

|||

Click to Enlarge

Figure 170A Parameters used to describe pulsed laser emission are indicated in this plot and described in Table 170B. Pulse energy (E) is the shaded area under the pulse curve. Pulse energy is, equivalently, the area of the diagonally hashed region.

| Table 170B Pulse Parameters | |||||

|---|---|---|---|---|---|

| Parameter | Symbol | Units | Description | ||

| Pulse Energy | E | Joules [J] | A measure of one pulse's total emission, which is the only light emitted by the laser over the entire period. The pulse energy equals the shaded area, which is equivalent to the area covered by diagonal hash marks. | ||

| Period | Δt | Seconds [s] | The amount of time between the start of one pulse and the start of the next. | ||

| Average Power | Pavg | Watts [W] | The height on the optical power axis, if the energy emitted by the pulse were uniformly spread over the entire period. | ||

| Instantaneous Power | P | Watts [W] | The optical power at a single, specific point in time. | ||

| Peak Power | Ppeak | Watts [W] | The maximum instantaneous optical power output by the laser. | ||

| Pulse Width |  |

Seconds [s] | A measure of the time between the beginning and end of the pulse, typically based on the full width half maximum (FWHM) of the pulse shape. Also called pulse duration. | ||

| Repetition Rate | frep | Hertz [Hz] | The frequency with which pulses are emitted. Equal to the reciprocal of the period. | ||

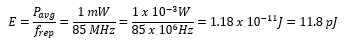

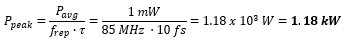

Example Calculation:

Is it safe to use a detector with a specified maximum peak optical input power of 75 mW to measure the following pulsed laser emission?

- Average Power: 1 mW

- Repetition Rate: 85 MHz

- Pulse Width: 10 fs

The energy per pulse:

seems low, but the peak pulse power is:

It is not safe to use the detector to measure this pulsed laser emission, since the peak power of the pulses is >5 orders of magnitude higher than the detector's maximum peak optical input power.

| Posted Comments: | |

Ahmet Becerikli

(posted 2024-11-13 09:01:40.047) Hello, I am not familiar with laser applications. Can I use ES145C (which is currently used for laser measurements) to measure the intensity of a battery driven LED lamp at 1-2 meter distance (to not oversaturate or damage the sensor)? I would connect it to a Picoscope (1 MOhm connection).

All I need to consider is not to exceed 2 J, right?

Best regards jjadvani

(posted 2024-11-15 02:13:01.0) Dear Ahmet, Thank you for your feedback. This is pyroelectric sensor and won’t be useful to measure the intensity of continuous light. I will contact you directly to provide you further information. user

(posted 2023-09-12 10:18:08.027) Hello, I am using an ES220C with a PM100USB. Sometimes, after connecting to the device (with no issues), we get the error "Timeout expired before operation completed" the first time measEnergy is called. This happens randomly (sometimes we are able to make measurements with no issues, and sometimes we are not). Also, occasionally we can make several measurements and then run into this error again. Can you let us know how we can avoid this issue? hkarpenko

(posted 2023-09-13 07:39:05.0) Dear customer,

thank you for your feedback.

The issue in this case might be, that the trigger level is set incorrectly. I will contact you directly to discuss this further with you. Kais Ben Khadhra

(posted 2023-07-31 14:02:16.683) Dear Madame/Sir,

I have a question about the maximum PRF which could ES408C receive. If I am not wrong the maximum PRF is 10 kHz? but in the power and energy calculation of the pulsed laser a PRF of 85 MHz has been used?

for my application I am searching of power sensor for high PRF (up to 400 MHz) pulsed laser and even for CW laser.

Best regards,

Dr.-Ing. MBA Kais Ben Khadhra

Artec 3D Luxembourg dpossin

(posted 2023-08-01 01:49:27.0) Dear Khadhra,

Thank you for your feedback. I am reaching out to you to provide further information. user

(posted 2023-04-19 11:25:35.407) Hi, the damage thresholds listed for the pyroelectrics sensors (such as the ES245C) are for uniform cross sections (top hat) or for Gaussian profiles? Also, how can i scale the damage thresholds for other pulses lengths? (the ones listed are for 7ns pulses) hchow

(posted 2023-04-20 05:10:26.0) Dear User, thank you for your feedback. The damage thresholds listed on the spec sheet of the ES245C are that for Gaussian beam profiles. The maximum power density: 65 MW/cm² (7 ns Pulse @ 355 nm) and maximum pulse energy density: 0.45 J/cm² (7 ns Pulse @ 355 nm) of the ES145C is given for pulse widths at 7 ns. If you take a look at the spec sheet PDF of the ES245C, on the middle graph of page 2, this graph illustrates the damage threshold with respect to the given pulse width length. You can refer to graph when you want to scale the pulse widths to higher values. Cagdas Yuksel

(posted 2023-01-03 17:40:30.67) Hi Dear,

We try to use ES220 with PM100D. However, refresh rate of the screen varies randomly. Also when we try to zero it the screen get frozen.

Do you have any user manuel for this product ?

Thank You. fmortaheb

(posted 2023-01-04 08:13:14.0) Thank you very much for contacting us. I will contact you directly for troubleshooting. user

(posted 2022-09-14 12:38:44.717) I use an ES111C sensor to detect 5ns pulses with a repetition rate of 10Hz. The integration time on the PM100USB software is 1 second, during which I measure on average 10 pulses. The measurement values are in mJ.

Are the displayed/measured values in the optical power monitor software the sum of 10 pulses or is it the average energy of 1 pulse?

Best, Jur wskopalik

(posted 2022-09-19 04:15:58.0) Thank you very much for your feedback!

With pyroelectric sensors such as the ES111C you can measure the energy contained in a single pulse. If you set the “Averaging” in the software to a number larger than 1, the software will calculate the average energy of the selected number of single pulses and will show this value.

I will contact you directly to provide further assistance. Julien Gorenflot

(posted 2022-08-19 00:32:11.323) Dear team,

I would like to know if the C-series energy sensors can accurately measure the energy of femtoseconsd and picosecond pulses, as the specs only mention about 10s of nanosecond. Additionally, is there some additional precautions to take for such short pulses.

Best regards,

Julien dpossin

(posted 2022-08-19 08:25:35.0) Dear Julien,

Thank you for your feedback. The damage threshold depends on the average power, the peak power density and the pulse energy. I reach out to you in order to discuss this in more detail. Dennis Clouthier

(posted 2022-04-05 12:02:45.887) I have a RS11C pyroelectric energy sensor. The black coating is slightly damaged. Is it possible for me to repair this and if so can you tell me how to do so? Thanks! wskopalik

(posted 2022-04-08 11:05:37.0) Dear Dennis,

Thank you very much for your feedback!

You can unfortunately not repair this yourself because the sensor element needs to be exchanged in this case and the sensor needs to be calibrated again with the new element. We can however repair and calibrate it in our facilities.

I will contact you directly to arrange the repair. John Linden

(posted 2021-08-15 22:37:02.877) I am looking for an energy meter to measure the profile and energy of a pulse from CO2 high power laser , 10.6um wavelength.

Can this product ES245C measure this? or it this the same as measuring total power as a S322C and then I would need a PDAVJ10 for profile sensing. Would I be able to then connect the power/energy meters to the PM400?

Appreciate you advice.

-John soswald

(posted 2021-08-18 07:50:06.0) Dear John,

thank you for your feedback.

If the pulse energy of your laser does not exceed the 1 mJ - 15 J range the ES245C can measure the pulse energy instead of the average power which the S332C measures.

Please keep the maximum repetition rate of 30 Hz and the maximum power density of 65 MW/cm² and maximum pulse energy of 0.45 J/cm² in mind.

The ES245C is compatible with our PM400 power meter console.

I have contacted you directly to discuss your application in more detail. 启元 吴

(posted 2020-11-16 13:59:35.863) 工程师您好,我们于今年九月份购买了贵公司的ES245C型号的热释电能量探头,用于对脉冲激光能量的测试。但是收到的探头序号和我们之前的不一样,一个是C552,一个是C730。使用这两个不同的探头测得的数据也是不一样的。我们安装旧的探头的时候,量程选择为100mj、1J等。但是用新的探头的时候,量程选择是140mj、1.4j等,使用新的探头测量得到的数据是老的探头的1.4倍。所以想请教一下这个问题到底是为什么、该怎么进行校准? wskopalik

(posted 2020-11-16 06:26:50.0) Thank you very much for your inquiry!

The energy ranges which are shown on the power meter display will be slightly different for each sensor. It depends on the exact responsivity of the attached sensor which is determined in the calibration procedure. The shown range will e.g. also change, if the wavelength is changed. The measured values should however be the same on all attached sensors.

We will contact you directly to provide further assistance. Vladimir Makarov

(posted 2020-08-26 14:21:40.587) Hi,

I am using the ES220C to measure laser energy. I am using a pulsed laser at 1000 Hz frequency. On the oscilloscope the signal from ES220C looks like a sawtooth wave where the signal never reaches 0V, but goes up/down with the firing of each pulse in the pulse-train.

I understand this setup exceeds the repetition rate spec of 30Hz of this sensor. Can you explain if the total energy detected would be inaccurate? It seems the laser keeps adding heat/energy to the meter at a high frequency, so the meter should still integrate this energy, correct?

Best,

Vlad M dpossin

(posted 2020-08-28 05:04:35.0) Dear Vladimir,

Thank you for your feedback. Well, the fact that pyroelectric sensors can only see signal changes, the measurement of higher repetition rates leads to wrong energy measurements. The energy is measured via the the time it takes between an incoming pulse exceeding the set trigger level and reaching the peak. In case the repetition rate of the laser source exceeds the sampling rate of the detector, the detector stays armed all the time which most leads to wrong measurements. I am reaching out to you in order to provide further support. song wei

(posted 2019-03-22 15:15:05.84) ES220C能量计接到PM100D表头上怎么使用?为什么用了几次没有读数? How to use the ES220C with PM100D? Why there is no respondance during my measurements? swick

(posted 2019-03-28 06:28:23.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

Usage of ES220C with PM100D is Plug&Play. If you get no energy reading please check settings energy range and trigger level.

I contacted you directly for troubleshooting. Jack Grigor

(posted 2019-03-15 11:29:57.383) can you tell me the relevance of the absorption graph shown for the ceramic coated ES245C detector? The specification quotes a measurement uncertainty of+/- 5% from 185 nm to 25 um, how does the absorption of the ceramic coating affect that when it drops by about 20% shortly after 1000nm? Does the detector responsivity not change at those longer wavelengths?

Thanks in advance. nreusch

(posted 2019-03-19 06:02:23.0) This is a response from Nicola at Thorlabs. Thank you for your inquiry! Generally speaking, a low responsivity of a detector system for certain wavelength ranges can lead to a reduced accuracy in this range. This is, however, only relevant if the responsivity is reduced by a lager factor. For e.g. our photodiode sensors, we specify different uncertainties for different wavelength ranges (3%, 5% or 7%). The 5% measurement uncertainty for ES245C is valid across the whole wavelength range. Bruce Melcher

(posted 2019-03-13 10:24:47.53) Is the ES220C sensor fast enough to respond to a single 7ns pulse at a 6mJ power level?

We are firing a single shot, 7ns, 6mJ, 1570nm Laser pulse into the ES220C sensor. We "appear" to get nothing but noise as an output (less than 1 mV). nreusch

(posted 2019-03-19 08:24:22.0) This is a response from Nicola at Thorlabs. Thank you for your inquiry. Pyroelectric sensors can resolve single pulses as long as the pulse energy is within the specified range. Please double check that the trigger level and the energy range are set correctly. We will contact you directly to provide further assistance. j.t.m.dehaas

(posted 2016-08-04 08:53:32.52) What is the input resistance of the BNC to DB9 mating adapter?

In other words what is the max. repetition rates of the sensor + the adapter?

Best regards

Johan swick

(posted 2016-08-04 06:00:28.0) This is a response from Sebastian at Thorlabs. Thank you very much for your inquiry.

The input resistance of the BNC-DB9 adapter is quite low and has no measurable effect on the repetition rate. The load resistance of our power meter consoles is 1MOhm, so with our power meter consoles (PM200, PM100D, PM100USB and PM320) and ES111C the maximum achievable repetition rate is 40Hz.

If the signal from ES111C is recorded with an other device than our power meter consoles, the maximum repetition rate (with 50kOhm) would be 100Hz. yuansuochao

(posted 2014-04-29 15:25:49.493) ES120C和145C能量计接到PM200表头上怎么使用?为什么用了几次没有读数?

How to use the ES120C with PM200? Why there is no respondance during my measurements? shallwig

(posted 2014-04-30 07:06:48.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. I am really sorry that you are experiencing difficulty with our ES120C sensor in combination with the PM200 power meter. These two units work together, perhaps the settings of the trigger level are not correct. If it is set too high the pulses will not be recognized by the device. On page 31 in the manual http://www.thorlabs.com/thorcat/19300/PM200-Manual.pdf we describe how to change this setting. In order to troubleshoot where your measurement problems come from and how to solve them I will contact you directly. sergii.yakunin

(posted 2013-10-16 09:19:32.03) Will ES111C head work with optically chopped CW light? tschalk

(posted 2013-10-16 11:18:00.0) This is a response from Thomas at Thorlabs. Thank you very much for your inquiry. An energy Sensor is not designed to work with a chopped light source. Therefore photo diodes or thermal sensors would be a better solution. I will contact you directly to discuss your application. julien

(posted 2011-01-28 04:50:28.0) A response from Julien at Thorlabs: Thank you for your feedback. The specification of the pulse length for the 150mJ/cm2 value is wrong and will be changed immediately. This max energy density corresponds to the maximum energy for long pulses (>1µs). Above this value the heat increase will bring the sensor above its Curie temperature and thus hamper its proper functioning. The curve in the spec sheet corresponds to the damage threshold of the adsorber surface. When damaged, the absorption of this surface will change and the responsivity of the sensor will be modified accordingly. matthew.bergkoetter

(posted 2011-01-26 16:26:55.0) The max pulse energy density for the ES111C is specified here on the webpage as 0.15J/cm2 for a 10ns pulse at 1064nm, however the PDF spec sheet seems to contradict this. Based on the plot titled "Pulse Energy Ratings and Damage Thresholds", the max energy density for a 10ns pulse would be more like 2mJ/cm2 - a discrepancy of two orders of magnitude. Which is correct? user

(posted 2010-09-21 05:45:39.0) Answer from Angelika at Thorlabs: The specification "max repetition rate" refers to the maximum data acquisition rate of the sensor. It is defined by the time constant of the sensor (time required to reach the initial sensor properties after a pulse). user

(posted 2010-09-10 06:44:52.0) Does the maximum repetition rate for the ES111C of 40Hz refer to the maximum data acquisition rate of the sensor or the maximum repetition rate of the laser to avoid damage to the sensor? julien

(posted 2010-08-11 12:30:55.0) A response from Julien at Thorlabs: the wavelength dependence of the damage threshold is related to absorption of the surface coating. As can be seen in the tab absorption graph, the absorption of the ES100 series is almost wavelength independent. The damage threshold specified can be thus used over the whole wavelength range of those sensors. user

(posted 2010-08-10 23:32:52.0) the Max Pulse Energy Density of ES111C is specified with 7ns pulse but at what wavelength? |

Click to Enlarge

Figure 113A The PM160 wireless power meter, shown here with an iPad mini (not included), can be remotely operated using Apple mobile devices.

This tab outlines the full selection of Thorlabs' power and energy sensors. Refer to Table 113B for power meter console and interface compatibility information.

In addition to the power and energy sensors listed below, Thorlabs also offers all-in-one, wireless, handheld power meters and compact USB power meter interfaces that contain either a photodiode or a thermal sensor, as well as power meter bundles that include a console, sensor head, and post mounting accessories.

Thorlabs offers four types of sensors:

- Photodiode Sensors: These sensors are designed for power measurements of monochromatic or near-monochromatic sources, as they have a wavelength dependent responsivity. These sensors deliver a current that depends on the input optical power and the wavelength. The current is fed into a transimpedance amplifier, which outputs a voltage proportional to the input current.

- Thermal Sensors: Constructed from material with a relatively flat response function across a wide range of wavelengths, these thermopile sensors are suitable for power measurements of broadband sources such as LEDs and SLDs. Thermal sensors deliver a voltage proportional to the input optical power.

- Thermal Position & Power Sensors: These sensors incorporate four thermopiles arranged as quadrants of a square. By comparing the voltage output from each quadrant, the unit calculates the beam's position.

- Pyroelectric Energy Sensors: Our pyroelectric sensors produce an output voltage through the pyroelectric effect and are suitable for measuring pulsed sources, with a repetition rate limited by the time constant of the detector. These sensors will output a peak voltage proportional to the incident pulse energy.

| Table 113B Console Compatibility | ||||||||

|---|---|---|---|---|---|---|---|---|

| Console Item # | PM100A | PM100D | PM400 | PM5020 | PM101 Series |

PM102 Series |

PM103 Series |

PM100USB |

| Photodiode Power |  |

|

|

|

|

- |  |

|

| Thermal Power |  |

|

|

|

|

|

- |  |

| Thermal Position | - | - |  |

|

- |  |

- | - |

| Pyroelectric Energy | - |  a a |

a a |

|

- | - |  |

a a |

Power and Energy Sensor Selection Guide

There are two options for comparing the specifications of our Power and Energy Sensors. Tables 113C, 113D, 113E, and 113F sort our sensors by type (e.g., photodiode, thermal, or pyroelectric) and provide key specifications.

Alternatively, the selection guide Figures 113G and 113H arrange our entire selection of photodiode and thermal power sensors by wavelength (Figure 113G) or optical power range (Figure 113H). Each box contains the item # and specified range of the sensor. These graphs allow for easy identification of the sensor heads available for a specific wavelength or power range.

| Table 113C Photodiode Power Sensors |

|---|

| Table 113D Thermal Power Sensors |

|---|

| Table 113E Thermal Position & Power Sensors |

|---|

| Table 113F Pyroelectric Energy Sensors |

|---|

Figure 113G Sensor Options Arranged by Wavelength Range

Figure 113G Sensor Options Arranged by Wavelength Range Figure 113H Sensor Options Arranged by Power Range

Figure 113H Sensor Options Arranged by Power Range

- For General Purpose Optical Pulse Measurements

- Black Broadband Coating with Flat Response Over a Wide Wavelength Range

- Ø11 mm, Ø20 mm, or Ø45 mm Sensor Area

- BNC Connector for Oscilloscope Use

- Each Sensor Includes:

- C-Series Connector Adapter for Use with Compatible Thorlabs' Consoles (See Table Below or the Console Selection Tab)

- Two Electrically Isolating Post Adapters (One Imperial and One Metric)

The ES1xxC Standard Pyroelectric Sensors are designed to measure pulsed coherent and incoherent sources. Pyroelectric sensors are not suited for CW measurements, as they convert energy from light pulses into voltage pulses. The black broadband coating on these sensors is ideal for low power, wavelength-independent energy measurements due to its flat absorption profile (see the table below). Large sensor areas of Ø11 mm, Ø20 mm, or Ø45 mm aid with easy alignment. The sensors can be connected directly to an oscilloscope with a 1 MΩ input resistance via the BNC connector. To accommodate higher repetition rates when connected to an oscilloscope, the load resistance can be reduced. Each energy sensor includes a BNC to C-Series adapter that contains NIST- and PTB-traceable calibration data.

Thorlabs offers a recalibration service for these energy sensors, which can be ordered below (see Item # CAL-THPY).

| Item #a | ES111C | ES120C | ES145C |

|---|---|---|---|

| Sensor Image (Click the Image to Enlarge) |

|

|

|

| Input Aperture Size | Ø11 mm | Ø20 mm | Ø45 mm |

| Wavelength Range | 0.185 - 25 µm | ||

| Energy Range | 10 µJ - 150 mJ | 100 µJ - 500 mJ | 500 µJ - 2 J |

| Max Repetition Rateb | 40 Hz | 30 Hz | 30 Hz |

| Max Power Density (Pulse Width) |

8 MW/cm2 (10 ns Pulse) |

||

| Max Pulse Energy Density (Pulse Width) |

0.15 J/cm2 (1 µs Pulse) |

||

| Coating (Click for Plot) | Black Broadband | ||

| Resolution | 100 nJ | 1 µJ | 1 µJ |

| Linearity | ±1% | ||

| Measurement Uncertainty | ±5% @ 190 nm - 25 µm | ±5% @ 185 nm - 25 µm | ±5% @ 185 nm - 25 µm |

| Housing Dimensions | Ø36 mm x 16 mm | Ø50 mm x 18 mm | Ø75 mm x 21 mm |

| Active Detector Area | 95.0 mm2 | 314.2 mm2 | 1590.4 mm2 |

| Cable Length | 1.5 m (60") | ||

| Post Mounting | 8-32 Mounting Thread, 8-32 and M4 Insulating Adapters Included | ||

| Cage Mounting | N/A | Four 4-40 Threaded Holes for 30 mm Cage Systems |

N/A |

| Compatible Consoles | PM400, PM100D, and PM5020 | ||

| Compatible Interfaces | PM103, PM103A, PM103E, PM103U, and PM100USB | ||

Click to Enlarge

ES220C Sensor Mounted in a 30 mm Cage System

- For High-Energy Optical Pulse Measurements Up to 15 J

- Ceramic Coating with High Damage Threshold for High-Energy-Density (Up to 0.45 J/cm2) Lasers

- Ø20 mm or Ø45 mm Sensor Area

- BNC Connector for Oscilloscope Use

- Each Sensor Includes:

- C-Series Connector Adapter for Use with Compatible Thorlabs' Consoles (See Table Below or the Console Selection Tab)

- Two Electrically Isolating Post Adapters (One Imperial and One Metric)

The ES2xxC High-Energy Pyroelectric Sensors are designed to measure pulsed coherent and incoherent sources. Pyroelectric sensors are not suited for CW measurements, as they convert energy from light pulses into voltage pulses. A ceramic coating is used for high energy measurements as high as 3 J for the ES220C sensor or 15 J for the ES245C sensor. Large Ø20 mm or Ø45 mm sensor areas aid with easy alignment. The sensors can be connected directly to an oscilloscope with a 1 MΩ input resistance via the BNC connector. To accommodate higher repetition rates when connected to an oscilloscope, the load resistance can be reduced. Each energy sensor also includes a BNC to C-Series adapter that contains NIST- and PTB-traceable calibration data.

Thorlabs offers a recalibration service for these energy sensors, which can be ordered below (see Item # CAL-THPY).

| Item #a | ES220C | ES245C |

|---|---|---|

| Sensor Image (Click the Image to Enlarge) |

|

|

| Input Aperture Size | Ø20 mm | Ø45 mm |

| Wavelength Range | 0.185 - 25 µm | |

| Energy Range | 500 µJ - 3 J | 1 mJ - 15 J |

| Max Repetition Rateb | 30 Hz | 30 Hz |

| Max Power Density (Pulse Width) |

65 MW/cm2 (7 ns Pulse @ 355 nm) |

|

| Max Pulse Energy Density (Pulse Width) |

0.45 J/cm2 (7 ns Pulse @ 355 nm) |

|

| Coating (Click for Plot) | Ceramic | |

| Resolution | 25 µJ | 50 µJ |

| Linearity | ±1% | |

| Measurement Uncertainty | ±5% @ 0.185 - 25 µm | |

| Housing Dimensions | Ø50 mm x 18 mm | Ø75 mm x 21 mm |

| Active Detector Area | 314.2 mm2 | 1590.4 mm2 |

| Cable Length | 1.5 m (60") | |

| Post Mounting | 8-32 Mounting Thread, 8-32 and M4 Insulating Adapters Included | |

| Cage Mounting | Four 4-40 Threaded Holes for 30 mm Cage Systems | N/A |

| Compatible Consoles | PM400, PM100D, and PM5020 | |

| Compatible Interfaces | PM103, PM103A, PM103E, PM103U, and PM100USB | |

- For Measurements of Repetition Rates up to 10 kHz

- Two Coating Options:

- Black Broadband Coating with Flat Response from 185 nm to 25 µm

- Metal Coating for 185 nm to 2.5 µm to Support Detecting Repetition Rates up to 10 kHz

- Ø8 mm or Ø12 mm Sensor Areas

- BNC Connector for Oscilloscope Use

- Includes C-Series Connector Adapter for Use with Compatible Thorlabs' Consoles (See Table Below or the Console Selection Tab)

These Fast Pyroelectric Sensors are designed to measure pulsed coherent and incoherent sources with high repetition rates up to 10 kHz. Pyroelectric sensors are not suited for CW measurements, as they convert energy from light pulses into voltage pulses. The ES3xxC sensors have a black broadband that provides a flat response from 185 nm to 25 µm, and, depending on the sensor size, can support measurements of repetition rates up to 1 kHz. The metal-coated E4xxC sensors can detect repetition rates up to 10 kHz, depending on the sensor size, over a more limited wavelength range of 185 nm to 2.5 µm. Ø8 mm or Ø12 mm sensor areas are available, and each input aperture has external SM1 (1.035"-40) threads for compatibility with our SM1-threaded lens tubes. These energy sensors have BNC connectors for connection to an oscilloscope with a 1 MΩ load input resistance; using these sensors with a different load resistance may lead to reduced speed. A BNC to C-Series adapter containing NIST- and PTB-traceable calibration data is also included with each sensor.

Thorlabs offers a recalibration service for these energy sensors, which can be ordered below (see Item # CAL-THPY).

| Item #a | ES308C | ES312C | ES408C | ES412C |

|---|---|---|---|---|

| Sensor Image (Click the Image to Enlarge) |

|

|

|

|

| Input Aperture Size | Ø8 mm | Ø12 mm | Ø8 mm | Ø12 mm |

| Wavelength Range | 0.185 - 25 µm | 0.185 - 2.5 µm | ||

| Energy Range | 500 µJ - 1 J | 100 µJ - 1 J | 100 µJ - 1 J | 50 µJ - 500 mJ |

| Max Repetition Rateb | 1 kHz | 250 Hz | 10 kHz | 2 kHz |

| Max Power Density (Pulse Width) |

8 MW/cm2 (10 ns Pulse) |

5 MW/cm2 (10 ns Pulse) |

||

| Max Pulse Energy Density (Pulse Width) |

80 mJ/cm2 (10 ns Pulse) |

50 mJ/cm2 (10 ns Pulse) |

||

| Coating (Click for Plot) | Black Broadband | Metal | ||

| Resolution | 5 µJ | 1 µJ | 1 µJ | 1 µJ |

| Linearity | ±1% | |||

| Measurement Uncertainty | ±5% @ 0.185 - 25 µm | ±5% @ 0.185 - 2.5 µm | ||

| Housing Dimensionsc | Ø38 mm x 15 mm | Ø38 mm x 15 mm | Ø38 mm x 15 mm | Ø38 mm x 15 mm |

| Active Detector Area | 50.3 mm2 | 113.1 mm2 | 50.3 mm2 | 113.1 mm2 |

| Cable Length | 1.5 m (60") | |||

| Post Mounting | 8-32 and M4 Combi Mounting Thread | |||

| Aperture Thread | External SM1 (1.035"-40) Thread Thread Depth: 3.0 mm (0.12") |

|||

| Compatible Consoles | PM400, PM100D, and PM5020 | PM5020 | PM400, PM100D, and PM5020 | |

| Compatible Interfaces | PM103, PM103A, PM103E, PM103U, and PM100USB | PM103, PM103A, PM103E, and PM103U | PM103, PM103A, PM103E, PM103U, and PM100USB | |

| Table 317A Compatibility | |

|---|---|

| Sensor Type | Sensor Item #s |

| Thermal Power | S175C, S302Ca, S305Ca, S310Ca, S314Ca,S322C, S350C, S370C, S401C, S405C, S415C, S425C, S425C-L, S470C, PM160T, PM160T-HP, PM16-401, PM16-405 |

| Pyroelectric Energy | ES111C, ES120C, ES145C, ES220C, ES245C, ES308C, ES312C, ES408C, ES412C |

Thorlabs offers recalibration services for our Thermal Power and Pyroelectric Energy Sensors. To ensure accurate measurements, we recommend recalibrating the sensors annually. Recalibration of a single-channel power and/or energy meter console or interface is included with the recalibration of a sensor at no additional cost. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually.

Please note that the CAL-THPY recalibration service cannot be used for our Thermal Position & Power Sensors; recalibration for these sensors can be requested by contacting Tech Support. Table 317A lists the sensors for which the CAL-THPY recalibration service is available.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #s, and the Serial #s of all sensors or consoles being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." All other fields are optional. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Enter the Part # and Serial # of the item that requires recalibration below and then Add to Cart. If you would like a console calibrated with your sensor, repeat this process for Item # CAL-PM1 or CAL-PM2 below, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate the return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team. Pyroelectric energy sensors returned for recalibration or servicing must include the separate BNC to DB9 adapter, which contains the sensor EEPROM.

| Table 719A Compatibility | |

|---|---|

| Calibration Service Item # | Compatible Consoles & Interfaces |

| Single-Channel | |

| CAL-PM1 | PM100D, PM100A, PM400, PM100USB, PM101 Series, PM102 Series, PM103 Series |

| Dual-Channel | |

| CAL-PM2 | PM5020, Previous-Generation PM320E |

These recalibration services are for the power and/or energy meter electronics of our consoles and interfaces. To ensure accurate measurements, we recommend recalibrating annually. Recalibration of a single-channel console or interface is included with these sensor recalibration services at no additional cost. If you wish to calibrate one or more sensors with a dual-channel console, each sensor and console calibration service will need to be purchased individually. For more details on these recalibration services, please click the Documents (![]() ) icons below.

) icons below.

Table 719A lists the power and/or energy meter consoles and interfaces that can be calibrated using the CAL-PM1 and CAL-PM2 recalibration services.

Requesting a Calibration

Thorlabs provides two options for requesting a calibration:

- Complete the Returns Material Authorization (RMA) form. When completing the RMA form, please enter your name, contact information, the Part #, and the Serial # of each item being returned for calibration; in the Reason for Return field, select "I would like an item to be calibrated." All other fields are optional. Once the form has been submitted, a member of our RMA team will reach out to provide an RMA Number, return instructions, and to verify billing and payment information.

- Select the appropriate Item # below, enter the Part # and Serial # of the item that requires recalibration, and then Add to Cart. If you would like to calibrate one or more sensors with your console, repeat this process for the appropriate sensor recalibration service above, entering the console Item # and Serial #. A member of our RMA team will reach out to coordinate return of the item(s) for calibration. Note that each console calibration Item # represents the cost of calibrating a console alone; if requesting a single-channel console calibration with a sensor calibration, the appropriate discount will be applied when your request is processed. Should you have other items in your cart, note that the calibration request will be split off from your order for RMA processing.

Please Note: To ensure your item being returned for calibration is routed appropriately once it arrives at our facility, please do not ship it prior to being provided an RMA Number and return instructions by a member of our team.

Products Home

Products Home

Pyroelectric Energy Sensors

Pyroelectric Energy Sensors