Custom Optical Breadboards and Tables Manufacturing

Please Wait

Tables, Breadboards, and Vibration Isolation Capabilities

Our team of experts is dedicated to creating high-quality

custom and standard optical tables and accessories.

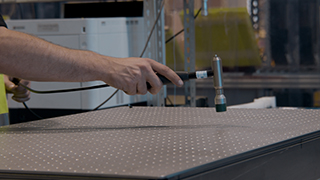

Click to Enlarge

Figure 1.1 Our Manufacturing Facility in Ely, UK

Based in Ely, UK, Thorlabs LTD. is home to the machinery and design resources necessary to develop both catalog and custom vibration isolation solutions, including optical tables, breadboards, and lab accessories.

For an overview of our table manufacturing process, see the video, or for more details, please refer to the other tabs. If you have special requirements, a custom application, or general questions about our capabilities, please contact Tech Sales to start a discussion.

Customization Options

- Active and Passive Isolation

- Custom Sizes and Shapes

- Sealed or Unsealed Holes

- Magnetic or Non-Magnetic Materials

- Joiner Systems

- Wide Range of Accessories, such as Frames, Shelves, HEPA Filters, Laser Safety Curtains, Optical Enclosures, and More

Tables, Breadboards, and Vibration Isolation Design and Manufacturing Process

Optical Tables

Since 2004, Thorlabs has been designing and manufacturing optical tables in-house. We produce high-performance optical tables for photonics, imaging, quantum, microscopy applications, and more. The design is an XYZ symmetrical, isotropic construction. Thermal stability is maximized by using only steel or aluminum. Our internal honeycomb structure is fabricated from strips of precision-crimped steel. The top and bottom plates are bonded to the honeycomb using a hot pressing method and a modified structural epoxy adhesive. The bond has a high tensile strength as well as an extremely high shear and peel strength. The finished table provides a stable work surface ideal for the most demanding applications. Each table is inspected before it leaves the factory. Learn more about the benefits and properties of optical tables in our tutorial here.

Breadboards

The Thorlabs catalog contains honeycomb, aluminum, and stainless steel breadboards in many sizes. We offer a variety of damping and stiffness options in addition to different thicknesses and shapes, vacuum compatibility, anodization, and temperature control customizations. Our in-house production teams are uniquely qualified to handle special requests for modifications to our catalog products. We can easily tailor the shape and size to suit your specific requirements. Special lengths and thicknesses can be manufactured, with or without access holes. Custom finishes, non-standard materials (e.g., virtually non-magnetic stainless steel), and customized damping solutions can also be provided.

Vibration Isolation

With design and manufacturing for tables, breadboards, vibration isolation equipment, and lab accessories co-located in Ely, UK, our team is well-prepared to tackle any isolation challenges you might face. We offer table supports that provide passive isolation or active self-leveling isolation and full frames with integrated isolation. Our catalog includes an air compressor and air regulator to easily set up active vibration isolation in your lab environment. Our team is able to recommend the proper accessories for your environment or design a custom system to ensure your experimental setup is stable.

Other Lab Accessories

In addition to a variety of vibration isolation equipment, Thorlabs designs, manufactures, and tests lab accessories, including laser curtain systems, laminar flow systems, workstation frames, shelving, optical enclosures, and more. Our ScienceDesk™ breadboard frames and optical table frames can serve as ergonomic workstations optimized for microscopy or photonics applications. To complete your setup, you can order a custom laser safety curtain system on our website or contact our Tech Sales team for assistance. Our other accessories enable you to design a completely custom work environment to suit your experimental needs.

Specials and Custom Orders

Custom design and manufacturing have been part of Thorlabs’ core capabilities from the start. In the beginning, this frequently involved making a small modification to a standard component so that a graduate student could realize their unique experimental setup. As the photonics industry has matured, so has our ability to customize designs, develop integrated solutions, and scale our production capacity and capabilities.

Optical tables are the foundation of any new lab. Interested in learning more about our New Lab Program? Additional information and the application form can be found on our webpage.

Manufacturing Capabilities

Our production team's overall goal is to utilize the latest technologies, lean manufacturing processes, and quality materials to enable us to rapidly produce consistent best-in-class products. We have made extensive investments in a broad range of dedicated machinery and processes including large-bed CNC mills, multi-point tooling systems, laminating presses, and fine finishing machines.

Our highly skilled production teams work in dedicated, resourced cells for machining, prepping, assembly, and finishing. Cross-training empowers our production personnel to float between different cells, adapting our output as production needs change.

From start to finish, every person in the manufacturing process is empowered to identify any potential quality issues regardless of whether it affects their operation. By embracing a total-quality approach to our manufacturing, we strive to provide the highest caliber tables, breadboards, and lab accessories in the photonics industry.

3- and 5-Axis Vertical Mills

Vertical mills are an extremely versatile resource for Thorlabs. We use them to prototype designs, produce initial production runs as the main production line is tooled and validated, and as the main production resource for a wide range of components. Many of our vertical mills have some form of automation that allows them to operate continuously during a shift, and in some cases, between shifts. Many mills feature multi-pallet systems that can be swapped in and out without tooling or setup.

Double Column Vertical Machining Centers

Highly accurate and precise cutting and milling operations are integral to machining our table tops and breadboards. Our Double Column Vertical Machining Centers offer enhanced cutting performance and multiple milling options. The machine features a heavy-duty cast iron bed construction for high accuracy and rigidity. The large size of the machine bed enables us to produce custom tables of sizes that exceed our catalog offering.

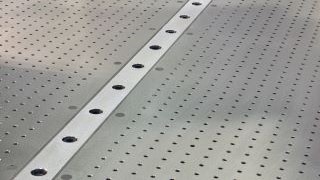

Multi-Point Tooling Systems

Our multi-point tooling systems perform a variety of manufacturing processes, not the least of which include drilling and tapping metric- or imperial-threaded holes into table skins and breadboards. We have high-speed machines that utilize drill-heads with up to eight bits for maximum efficiency. These tools are highly configurable to meet our unique requirements.

Steel Crimping

Our machine works is home to several different precision steel crimping machines. We form the symmetrical core of our optical tables from strips of this precision-crimped steel using accurate pressing tools and a high-tensile-strength epoxy adhesive. The result is steel or aluminum plates separated by an interior steel or aluminium honeycomb structure. The honeycomb structure is designed to maximize stiffness while keeping the weight low, and the plates provide a stiff, flat working surface.

Laser Cutting

Laser cutting is another versatile capability utilized in our manufacturing process. The edges of our tables as well as the flat shims that are integral to the interior structure of our optical tables are cut using a high-power laser system. Laser cutting also enables more options for customization, including sizes, shapes, and joiner systems.

Polishing and Fine Finishing

While post-machining finishing processes typically receive little attention, we consider them integral to the final product. Every table and breadboard surface is machine-polished ahead of final inspection. Laser engraving and screen printing are also performed in-house.

Glueing

We use various tools to speed up the glueing process. The top and bottom plates are bonded to the honeycomb using a hot pressing method and a modified structural epoxy adhesive. The adhesive is either hot-pressed or cured under vacuum. This results in a bond between the various pieces of the composite structure that has a high tensile strength as well as extremely high shear and peel strengths. The resulting tables and breadboards provide a stable work surface ideal for the most demanding applications.

Metrology and Quality

Click to Enlarge

Figure 3.1 Catalog and custom orders are subjected to rigorous testing, including thread verification and vibration transmissibility.

Click to Enlarge

Figure 3.2 We have conducted compliance testing to produce a frequency response spectrum (i.e., a compliance curve) for every table size and leg.

Click to Enlarge

Figure 3.3 Customized metrology and testing are available for custom orders, such as this table joiner system.

- Laser Measurement Systems

- Thread Verification

- Broadband Damped Tuning

Our volume production designs are subject to routine inspection to ensure that they meet defined key function specifications. These inspections include flatness, surface finish, reflectivity, and compliance testing of breadboards, tabletops, and support structures. For compliance testing, an impulse hammer is used to apply a measured force to the top surface of the table or breadboard, and transducers attached to the surface detect the resultant vibrations. The signals from the transducers are interpreted by the analyzer and used to produce a frequency response spectrum (i.e., a compliance curve). Each table size and leg variation has been tested and the compliance data is available here.

To inquire about custom testing or specifications, please contact Tech Sales.

Customization Options

Click to Enlarge

Figure 4.1 A custom table joiner system is assembled and inspected prior to being shipped to a customer.

- Large, Multiple-Table Joined Systems

- Custom Shapes, Materials, and Finishes for Breadboards and Tables

- Sealed or Unsealed Holes

- Magnetic or Non-Magnetic

- Rigid, Passive, or Active Leveling Isolation

- Custom Frames or Table Supports

- Custom Laser Curtain Sizes or Systems

- Custom Optical or HEPA Enclosures

- Cleanroom Compatible

- OEM Capabilities

- Dedicated Staff for Processing Quotes, Determining Pricing, and Producing Manufacturing Drawings

Our in-house production teams are uniquely qualified to handle special requests for modifications to our catalog products. Tables can be provided with special plates that allow two or more units to be securely coupled together into a single monolithic structure. We can also tailor the shape and size to suit your specific requirements. Special lengths and thicknesses can be manufactured, with or without access holes and cutouts for beam steering or cable routing. Custom finishes and non-standard materials (e.g., virtually non-magnetic stainless steel) can also be provided.

To submit a quote request for a custom optical table or breadboard, please use our Custom Table and Breadboard Request Form.

| Posted Comments: | |

user

(posted 2023-01-08 18:53:17.857) There is a typo in the Japanese page, "設計" tab:

> そしてもう1つは乞うk学テーブルの振動を十分に減衰させること

「乞うk学」should be 「光学」. DCroxford

(posted 2023-01-10 05:32:43.0) Thank you for bringing this to our attention. A representative in your local office has been notified and will look into this. Oren Berger

(posted 2022-10-04 21:43:05.437) Hello,

I just recieved an optical table that i have purchased from you.

The surface is very dirty. When i sweep my hand on it my hand remains with a silvery looking residue like a silver paint.

First of all i hope it does not have any health issues for my staff. Is it?

Second, do you have a standard proceedure to clean this residue?

Exactly which materials can be used to clean the stainless steal breadboard without damaging it?

Which cloth to use?

Do you have this kind of cleaning materials and cloths that you can send me?

I will order soon more optical tables. How can i make sure that next time the tables will be clean?

Regards,

Oren cwright

(posted 2022-10-05 06:09:50.0) Response from Charles at Thorlabs: Thank you for your query. We are sorry to hear that your table arrived in this state. This could be from our finishing processes and is normally removed during processing. Unfortunately it appears you have received an outlier. We will reach out to you about this and how it can be cleaned. |

Products Home

Products Home

Table and Breadboard Manufacturing

Table and Breadboard Manufacturing